"Traditionally, we used systems that processed 9,000 t/hour, but now many projects require systems capable of handling 15,000 t/hour, with some plants even planning to operate multiple lines at that scale."

RELATED PUBLICATION

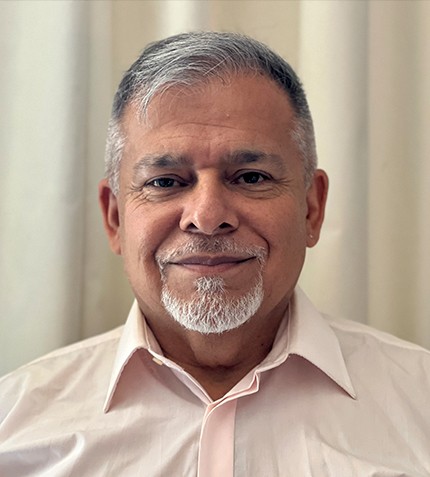

Sergio Zamorano

CEO, FAM

Can you summarize FAM's 2024, including key projects and milestones?

For FAM, part of BEUMER Group, this year marked our largest order intake in our 24 years in Chile. We secured some remarkable projects, including two for Codelco. One involves a conveyor upgrade, while the other includes what will be the largest spreader in the southern hemisphere and the Americas—likely the largest built in the 21st century. The project is a completely new concept designed to meet a unique requirement of operating on a mountain slope.

Why is such a machine needed in mining presently?

As we face lower ore grades that require more waste removal, we increasingly need larger capacities to meet demand. When I returned to Chile 30 years ago, many of the mines we now work with were expected to close by the 2000s due to low grades. However, the rising demand for copper has made it economically viable to process ore that seemed unfeasible two decades ago. This shift is not confined to just one operation; traditionally, we used systems that processed 9,000 t/hour, but now many projects require systems capable of handling 15,000 t/hour, with some plants even planning to operate multiple lines at that scale.

What technologies are driving your mining innovations?

We are combining traditional experience-based structural analysis and mechanical expertise with cutting-edge technologies like digitalization, image recognition, and automation. Our strategy also includes enhancing client access to real-time support. This global network enables us to advance digitalization as a core part of our strategic development. This shift also includes more advanced, sometimes autonomous, control systems and smarter communication methods, while our expertise pool allows us to confidently set a new benchmark with a pipe conveyor project involving a 26-degree incline and 3,000 t/hour of copper ore.

What role does Chile play in global mining innovation?

In the 21st century, Chileans are poised to play a major role in shaping the future of material handling, thanks to a strong tradition and hands-on learning approach. The key to success in this field is practical experience. Chile’s demographic advantage lies in its strong cultural respect for mining, which remains integral to the national identity. Unlike in Europe or Brazil, where mining has lost some of its appeal, mining continues to drive the economies of Chile and Peru, contributing significantly to their exports. As a result, Chile is well-positioned to continue its legacy of innovation, with a new generation eager to learn and lead. By mid-century, experts from Chile, India, and South Africa will likely be at the forefront of the industry, drawing from past lessons to shape its future.

How is your progress with the carbon-neutral warehouse?

Last month, we reached a significant milestone by not only achieving carbon neutrality but also becoming financially neutral in terms of energy costs. The efficiency of our solar panels in La Negra, Antofagasta, has been exceptional, generating around 60% of installed capacity within 12 hours of sunlight, effectively eliminating our energy expenses. We have made incremental progress toward greater sustainability, such as transitioning administrative vehicles to smaller, more fuel-efficient models. However, fully electric mining trucks remain unfeasible due to long distances, high elevation changes, and insufficient charging infrastructure.

How do you balance international standards with the realities of operating in Chile?

In 2023-2024, we set a safety benchmark within our group, achieving over a million accident-free work hours, with mining operations in Chile and Peru maintaining a strong safety focus. In sustainability, we collaborate globally to align efforts, although locally we lag behind innovations like China’s 14 km solar-powered conveyor. Acknowledging regional differences, we foster continuous discussions and knowledge-sharing.

What are FAM's strategies and goals for the future in Chile?

Our growth is exceeding expectations, positioning us strongly in the market as we prepare for substantial demand for material handling. Key challenges and opportunities include advancing technologies such as tailings handling, pipe conveyors, and large crawler-mounted machines, ensuring our continued activity in the industry.

Could you comment on your strategy for the broader Latin American region?

Peru offers significant opportunities through new projects and the expansion of existing operations, particularly in services. In Brazil, we maintain a strong position and foster collaboration. We also see potential in Argentina, where we are partnering with a local company to support growth.