Turn your injection leaching project into an opportunity, not a risk

Article header image by Jorge at Adobe Stock

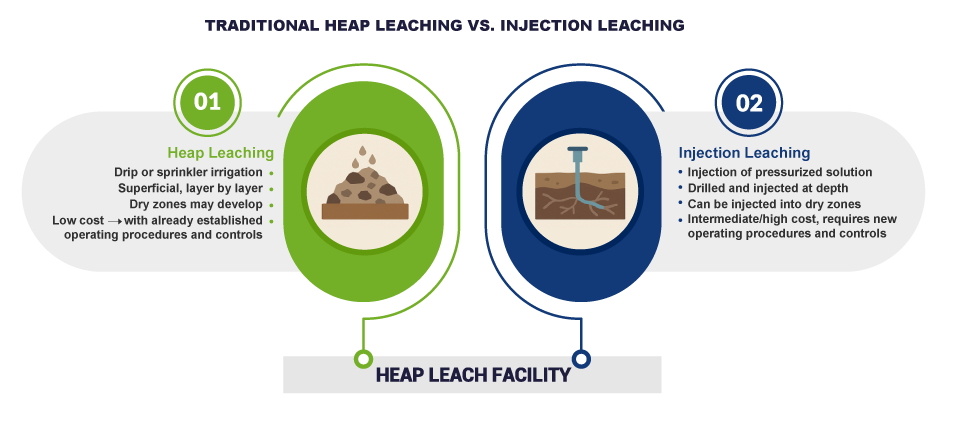

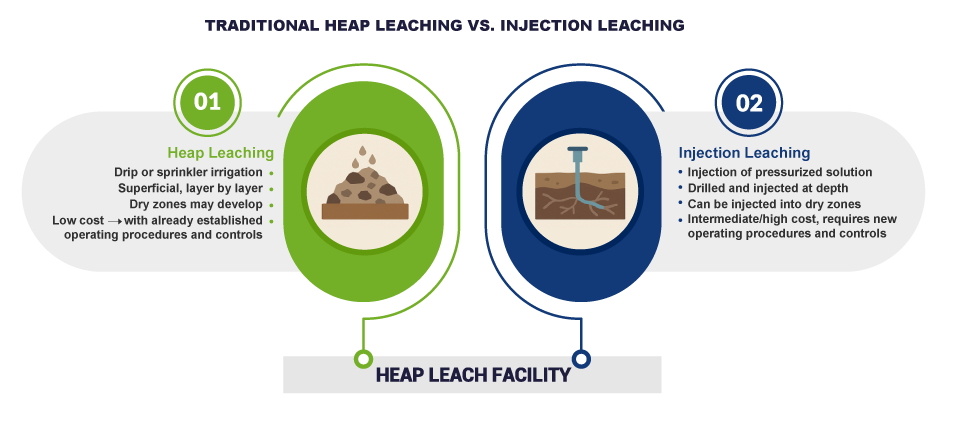

Peru is well known for hosting several major leaching projects, many of which are recognized as world-class operations. In simple terms, these projects consist of stacking extracted ore into large, tall pads that are irrigated with cyanide or acidic solutions to extract valuable minerals. Although effective, the process builds up an “inventory” of unprocessed ore because of the material’s heterogeneity and the limitations of conventional irrigation methods. To reduce that inventory, several techniques have emerged, including in-situ pressure leaching. The method uses injection wells drilled directly into the pad to apply pressurized solutions, mobilizing previously unrecovered ore.

The approach has gained particular interest in Peru, where many leach pads are nearing closure and operators want to recover additional value before shutting down. As with any technology, in-situ leaching presents challenges and risks, so a systematic and multidisciplinary approach is recommended to capture the upside while avoiding potential problems.

This systematic approach will not only improve mineral recovery but also help mitigate associated risks, turning a potential challenge into a tangible opportunity. When done correctly, in-situ injection leaching allows mining projects in Peru and around the world to achieve operational efficiency and sustained profitability without compromising safety or the environment.

Interesting facts:

Although leaching is considered a modern technique, the idea of using liquids to extract metals has ancient roots. Civilizations such as the Romans used early leaching methods to extract copper from oxidized ores using water and vinegar

Article header image by Jorge at Adobe Stock

Peru is well known for hosting several major leaching projects, many of which are recognized as world-class operations. In simple terms, these projects consist of stacking extracted ore into large, tall pads that are irrigated with cyanide or acidic solutions to extract valuable minerals. Although effective, the process builds up an “inventory” of unprocessed ore because of the material’s heterogeneity and the limitations of conventional irrigation methods. To reduce that inventory, several techniques have emerged, including in-situ pressure leaching. The method uses injection wells drilled directly into the pad to apply pressurized solutions, mobilizing previously unrecovered ore.

The approach has gained particular interest in Peru, where many leach pads are nearing closure and operators want to recover additional value before shutting down. As with any technology, in-situ leaching presents challenges and risks, so a systematic and multidisciplinary approach is recommended to capture the upside while avoiding potential problems.

This systematic approach will not only improve mineral recovery but also help mitigate associated risks, turning a potential challenge into a tangible opportunity. When done correctly, in-situ injection leaching allows mining projects in Peru and around the world to achieve operational efficiency and sustained profitability without compromising safety or the environment.

Interesting facts:

Although leaching is considered a modern technique, the idea of using liquids to extract metals has ancient roots. Civilizations such as the Romans used early leaching methods to extract copper from oxidized ores using water and vinegar